Rootstock Reviews & Pricing

- Food Safety Software

- 3D Printing Software

- Additive Manufacturing Software

- Aerospace Manufacturing Software

- Apparel ERP Software

- Apparel Manufacturing Software

- APS Software

- Automotive Manufacturing Software

- Bill Of Materials Software

- Business Management Software

- CAE Software

- Capacity Planning Software

- Chemical Manufacturing Software

- Discrete Manufacturing Software

- Distribution Inventory Management Software

- Distribution Software

- Electronics Manufacturing Software

- ERP Software

- Food Distribution Software

- Food Manufacturing Software

- Food Traceability Software

- Healthcare ERP Systems

- Higher Education ERP Systems

- Lean Manufacturing Software

- Manufacturing Accounting Systems

- Manufacturing BI Software

- Manufacturing Inventory Software

- Manufacturing Software

- Metal Fabrication Software

- MRO Software

- MRP Systems

- OEE Software

- Pharmaceutical Manufacturing Software

- Production Management Software

- Quality Management Software

- Simulation Software

- SPC Software

What is Rootstock?

Industry Specialties: Aerospace and defense, medical devices, industrial machinery, discrete manufacturing, engineer-to-order, high-tech electronics, cannabis manufacturers and wholesale distributors.

Rootstock Manufacturing ERP is a cloud-based platform that combines finances, supply chain, distribution, production and customer relationship management into one centralized platform built on Salesforce. Through this connectivity, it can automate tasks, improve productivity and reduce human error. It’s highly configurable and allows users to gain insights based on unique business requirements.

Notable features include capabilities for engineer-to-order (ETO), configure-to-order (CTO) and project-based manufacturing to manage complex projects and outsourced production. The 360-degree customer data view improves collaboration between sales and operations teams for a smoother quote-to-cash process.

It’s mobile-friendly and available for deployment in the cloud, making it highly accessible to a range of users. It’s suitable for businesses of varying sizes and industries.

To learn more about Rootstock, visit their company profile.

Rootstock Pricing

Based on our most recent analysis, Rootstock pricing starts at $200 (Per User, Monthly).

- Price

- $$$$$

- Starting From

- $200

- Pricing Model

- Per User, Monthly

- Free Trial

- No

Training Resources

Rootstock is supported with the following types of training:

- Documentation

- In Person

- Live Online

- Videos

- Webinars

Support

The following support services are available for Rootstock:

- Phone

- Chat

- FAQ

- Forum

- Help Desk

- Knowledge Base

- Tickets

- Training

- 24/7 Live Support

Rootstock Benefits and Insights

Key differentiators & advantages of Rootstock

- Adjust and Scale: Configure the system as business needs change or grow. Add new modules, alter dashboards to show relevant insights and define elements such as warranties to meet company goals.

- Connect Business Workflows: Connect various business workflows in a centralized location. Improve forecasting accuracy, order processing and inventory levels across networks with connected workflows and integrated supply chain apps.

- Access Data From Anywhere: Monitor workflows and dashboards from any location and device with cloud access.

- Work Smarter and Faster: Use advanced analytics and artificial intelligence to uncover patterns, bottlenecks and business trends. Get best practices and courses of action recommendations.

- Improve Operational Agility: Streamline workflows and automate management tools to improve operational agility and adapt to dynamic customer needs and business challenges. Uncover new opportunities and markets and deliver products faster.

- Stay Connected: Strengthen supplier relationships, minimize stockouts and ensure consistent materials flow with access to centralized databases. Enable uninterrupted production by letting users stay connected with people across departments.

- Gain a 360-Degree View: Gain complete visibility of end-to-end business processes and customer interactions. Empower informed decisions with access to customer, inventory, production and financial data in a single platform. Ensure transparent communication between vendors’ suppliers, manufacturers, distributors and customers. View real-time inventory metrics based on location, serial number and lot number.

- Focus on Manufacturers: Use features specifically designed for unique manufacturing needs. Simplify complex workflows, from engineer-to-order processes to supply chains and inventory levels.

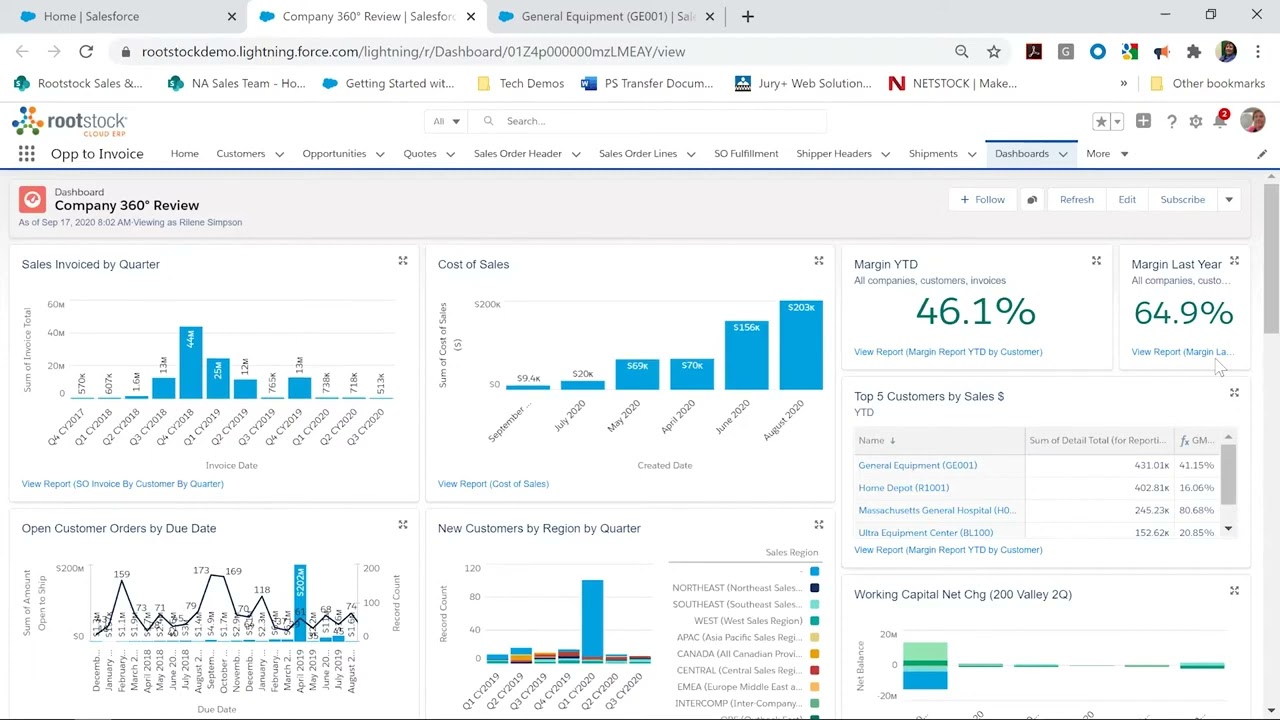

- Customize Dashboards: Create personalized dashboards for any role within the organization, from CEO to salesperson. Let users identify trends, opportunities and potential threats at a glance. Drill down and analyze specific KPIs with a single click to make more effective decisions.

Industry Expertise

Rootstock Reviews

Based on our most recent analysis, Rootstock reviews indicate a 'great' User Satisfaction Rating of 81% based on 63 user reviews from 3 recognized software review sites.

Synopsis of User Ratings and Reviews

Based on an aggregate of Rootstock reviews taken from the sources above, the following pros & cons have been curated by a SelectHub Market Analyst.

Pros

Cons

Researcher's Summary:

Key Features

- Core Financials: Control all financial operations with fully supported out-of-the-box features like bank account reconciliation, general ledger management, invoicing, budget creation, project accounting and financial audit management.

- Procurement Management: Rely on a vendor master record for quick access to vendor details and track billing with three-way matching. Create and submit purchase requests and RFQs, and track them with filters like user requests, due dates, status and more. View discrepancies and choose to override, write off and process approvals using standard approval flows.

- Manufacturing: Manage vital functions like creating and revising single and multi-level bills of materials (BOM). Create and route jobs manually or automatically with the required information. Create, store and retrieve dispatch lists detailing each job, priority, location, order number and job status.

- Inventory Management: Access a master inventory list for all inventory-related settings. Review and adjust transactions to either increase or decrease the existing inventory of an item in a specific stock location ID/number. Manage stock reservation and replenishment with ease. Build and disassemble kits for sale and work orders.

- Warehouse Management: Enable multi-warehouse, multi-location planning and fulfillment with the distribution requirements planning (DRP) module. Receive advanced shipping notices (ASN) for outbound EDI 856 transactions. Enable labor planning and scheduling based on labor standards, work center resources and calendars. Determine resource availability and identify overload conditions.

- Order Management: Create purchase orders for dropshipping by including and adjusting the ship-to addresses. Get automatic estimates and convert quotes from Salesforce into the system to create orders for stock items, kits, configured products and non-physical items. Access sales order history and allow users to split order invoices into two batches.

- Project Management: Define various projects with the project workbench tool. Capture active projects as revenues or costs, and get real-time snapshots of project data. Use project charge codes to label various ad hoc activities and job codes for pre-defined actions.

- Analytics and Reporting: Leverage the Salesforce Data Loader to export data into CSV files. Create standard reports on account payables and receivables, cycle counts and more with multiple reporting formats. Access dashboards to review financial and operational metrics.

Approach to Common Challenges

- Adapting to Multiple Manufacturing Modes: Avoid production disruptions with inventory strategies designed for various manufacturing modes.

- Managing Complex Projects: Ensure timely deliveries with better supplier collaborations and order management capabilities for personalized or highly customized products.

- Estimating Profitability: Collect accurate financial data and apply business intelligence across various manufacturing operations for consistent and predictable profitability calculations.

- Eliminating Data Silos: Rely on a single data model built on Salesforce for all manufacturing, production and supply chain information. Provide better customer service, identify upsell and cross-sell opportunities, and align manufacturing processes with customer demand.

Cost of Ownership

Limitations

- Doesn’t offer joint venture management capabilities.

- Isn’t available for on-premise or hybrid deployment.

Demo Resources

- Recorded Demos: Rely on presentations or explainer videos about the core functionalities and features.

- Documentation: Refer to user manuals, white papers and knowledge base articles while working with the system.

- Live Online: Connect with sales representatives for an interactive learning experience and real-time query resolution.

FAQs

- Accessibility: Access data from anywhere with an internet connection.

- Scalability: Scale or extend system capabilities as business needs evolve.

- Reduced IT Costs: No need to invest in expensive hardware or software maintenance.

- Automatic Updates: Benefit from the latest features and security patches.

- Synchronized Data: Ensure customer and product information is consistent across both systems.

- Improved Collaboration: Let sales, manufacturing and customer service teams collaborate more effectively.

- Enhanced Customer Experience: Deliver a more personalized experience by analyzing customer needs.

Customers

A note from Rootstock Software

In terms of AI, manufacturers are all in. The challenges we’ve seen include 1) disconnected silos of information, 2) an AI skills gap, and 3) the need for greater productivity.

At Rootstock, our solutions are designed for manufacturers, so we inherently understand their needs. That's why we’re able to focus on AI that truly matters to manufacturers. Built on Salesforce and Einstein 1, Rootstock offers the advantage of a connected Signal Chain strategy that balances demand, supply, and capacity. We’re honing both generative and predictive AI, so customers can leverage their data in a comprehensive Decisioning Platform. This enables a future in which business intelligence informs predictive and prescriptive insights, so customers drive decisions for enhanced value and productivity.

We’re also accelerating the adoption of AI by offering an AI Center of Excellence with data scientists and analysts helping customers configure decisioning models to their needs.